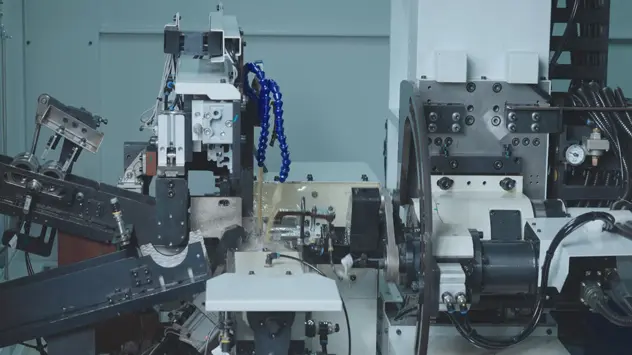

Automatic bearing inner and outer ring groove superfinishing machine for ball bearings, all available in dual-station configurations, are precision tools designed to enhance the surface finish and roundness of ball bearing components. These machines utilize fine abrasive stones or tapes to remove microscopic material, achieving superior surface quality and dimensional accuracy.

Key features include high-speed spindles, automated control systems, and customizable settings to accommodate various bearing sizes and materials.

Ideal for industries requiring high-performance bearings, such as automotive, aerospace, and industrial machinery, these machines ensure extended bearing life, reduced friction, and improved overall performance.

1. Ultra-Fine Ball Bearing Surface Finish

Our advanced ball bearing polishing system combines mechanical superfinishing with tape and slurry systems, achieving Ra ≤ 0.02 µm for mirror-finish surfaces, critical in low-noise, high-speed bearing applications.

2. CNC-Controlled Precision

Every ball bearing CNC machine in our lineup is equipped with servo-controlled axes, programmable tooling positions, and real-time diameter correction for consistent part-to-part quality.

3. Optimized for High Throughput

These machines are designed for multi-station operation (up to 8 heads per line) and can integrate seamlessly into automatic production cells, making them ideal ball bearing making machines for high-volume manufacturing.

4. Integrated Ball Bearing Grinding & Polishing

Eliminate the need for separate machines—our hybrid solution combines the roles of a ball bearing grinding machine, ball bearing grinder, and superfinishing system in a single footprint.

5. Modular Automation Ready

Options include auto-loading systems, vibration feeders, robotic arm interface, in-line measurement stations, and remote monitoring. Suitable for Industry 4.0 integration.

Ball Diameter Range: 2 mm to 50 mm

Station Types: Rough grind, finish grind, polishing, cleaning

Tool Life Monitoring: Real-time wear compensation

Tool Materials: CBN, diamond, alumina, and polishing tape

Coolant System: Filtered oil or emulsified fluid, with closed-loop design

A Superfinishing Machine for Ball Bearings is designed to enhance the surface finish and dimensional accuracy of ball bearings. Key components include:

Workpiece Spindle: Holds and rotates the ball bearings.

Abrasive Stone or Tape: Applies the superfinishing process to the bearing surface.

Pressure Control System: Regulates the force applied by the abrasive material.

Coolant System: Reduces heat and removes debris during the process.

Control Panel: Allows operators to set and monitor machine parameters.

Feed Mechanism: Ensures consistent movement of the abrasive material over the bearing surface.

These components work together to achieve a high-quality finish, improving the bearing’s performance and lifespan.

Call us on:

Call us on:  Email Us:

Email Us:  No. 52-1 Zhang Road, Meicun Industrial Park, New District, Wuxi City, Jiangsu, China.

No. 52-1 Zhang Road, Meicun Industrial Park, New District, Wuxi City, Jiangsu, China.