2025-03-22

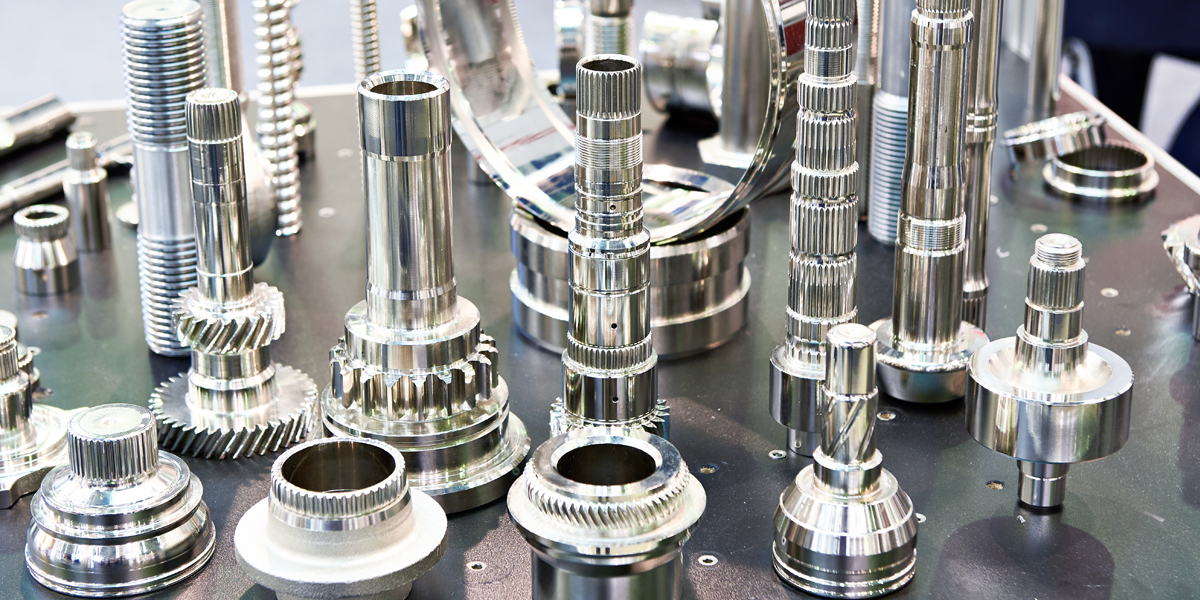

Bearing from the mill often have a finish that is not particularly smooth or aesthetically pleasing. To improve their surface quality and appeal, and superfinishing processes must be used.

Superfinishing, also known as microfinishing and short-stroke honing.

Superfinish machining significantly improves the roundness and roughness of the bearings surfaces and achieves the highest quality.

There is full surface contact between the tool and the workpiece, after machining, the bearings also have a higher load capacity and longer service life as well as lower running noise.

Superfinishing is a perfect process and a unique technology.

Bearings coming directly from milling or grinding operations often meet basic dimensional requirements, but their surface finish is usually not optimal for high-performance applications. These surfaces may show grinding marks, micro-roughness, or residual stress, which negatively affect bearing noise, friction, and service life.

To achieve the surface quality demanded by modern bearing applications, superfinishing is an essential process.

Superfinishing, also known as microfinishing or short-stroke honing, is a precision surface refinement process performed after grinding. Unlike conventional finishing methods, superfinishing removes only a very small amount of material—typically 1–2 microns—while dramatically improving surface integrity.

This process focuses not on changing geometry, but on refining the surface layer of the bearing raceway or rolling element to achieve ultra-low roughness and optimal contact conditions.

Superfinish machining significantly enhances both roundness and surface roughness of bearing components. Grinding defines the shape, but it also leaves behind microscopic peaks, valleys, and thermal damage. Superfinishing removes this damaged layer and produces a plateaued surface structure.

As a result:

Surface roughness (Ra) can be reduced to 0.01–0.02 μm

Raceway roundness and waviness are further stabilized

Surface consistency becomes highly repeatable across batches

This level of finish represents the highest surface quality standard achievable in bearing manufacturing.

One of the key advantages of superfinishing is that it creates full and uniform surface contact between the bearing components during operation.

Instead of point or line contact caused by surface asperities, the superfinished surface allows the load to be distributed evenly across the raceway.

This leads to:

Higher load-bearing capacity

Reduced localized stress

Improved fatigue resistance

More stable lubrication film formation

These factors directly translate into longer bearing service life under both high-speed and heavy-load conditions.

Bearings with untreated or poorly finished surfaces tend to generate higher vibration and noise during operation. Superfinishing eliminates surface irregularities that cause micro-slippage and friction fluctuations.

After superfinishing:

Running noise is significantly reduced

Friction coefficient is lowered

Heat generation during operation decreases

Overall energy efficiency improves

This is especially critical for automotive, electric motor, and high-speed precision bearings, where NVH (noise, vibration, harshness) performance is a key quality indicator.

Superfinishing is not an optional cosmetic process—it is a mature, highly specialized, and proven technology widely adopted by leading bearing manufacturers worldwide.

Its uniqueness lies in its ability to combine:

Extremely fine material removal

Low-pressure, controlled contact

Consistent and repeatable results

Functional surface optimization rather than visual appearance

Because of these advantages, superfinishing has become a standard process in high-end bearing production lines.

Superfinishing transforms bearings from "dimensionally correct" to functionally superior.

By improving surface roughness, roundness, load distribution, noise performance, and service life, it ensures bearings meet the increasing demands of modern machinery.

For manufacturers targeting high reliability, long lifespan, and premium performance, superfinishing is not just a finishing step—it is a critical quality assurance process and a competitive advantage.

Application and Advantages of Superfinishing Machines in Surface TreatmentJanuary 13, 2026Basic Principles and Working Mechanism of Superfinishing MachineThe superfinishing machine is a high-precision surface treatment device mainly used for micron-level surface processing of materials lik...view

Application and Advantages of Superfinishing Machines in Surface TreatmentJanuary 13, 2026Basic Principles and Working Mechanism of Superfinishing MachineThe superfinishing machine is a high-precision surface treatment device mainly used for micron-level surface processing of materials lik...view What Industries Benefit Most from Super Finisher Machines?November 14, 2025Industries that require high precision, low friction, and long component life benefit most from super finisher machines — including automotive, aerospace, bearing manufacturing, hydraulic, medical, a...view

What Industries Benefit Most from Super Finisher Machines?November 14, 2025Industries that require high precision, low friction, and long component life benefit most from super finisher machines — including automotive, aerospace, bearing manufacturing, hydraulic, medical, a...view Can Superfinishing Replace Traditional Polishing Processes Entirely?November 14, 2025In most precision industries, superfinishing has already replaced traditional polishing for critical components — but not in every case.A super finishing machine delivers far superior control over su...view

Can Superfinishing Replace Traditional Polishing Processes Entirely?November 14, 2025In most precision industries, superfinishing has already replaced traditional polishing for critical components — but not in every case.A super finishing machine delivers far superior control over su...view Call us on:

Call us on:  Email Us:

Email Us:  No. 52-1 Zhang Road, Meicun Industrial Park, New District, Wuxi City, Jiangsu, China.

No. 52-1 Zhang Road, Meicun Industrial Park, New District, Wuxi City, Jiangsu, China.