2025-11-27

The superfinishing process is a precision surface refinement method designed to remove the damaged layer left after grinding and achieve extremely low surface roughness — often reaching Ra ≤ 0.02 µm.

Unlike grinding or polishing, superfinishing focuses on enhancing surface integrity, improving lubrication behavior, and extending the service life of critical components.

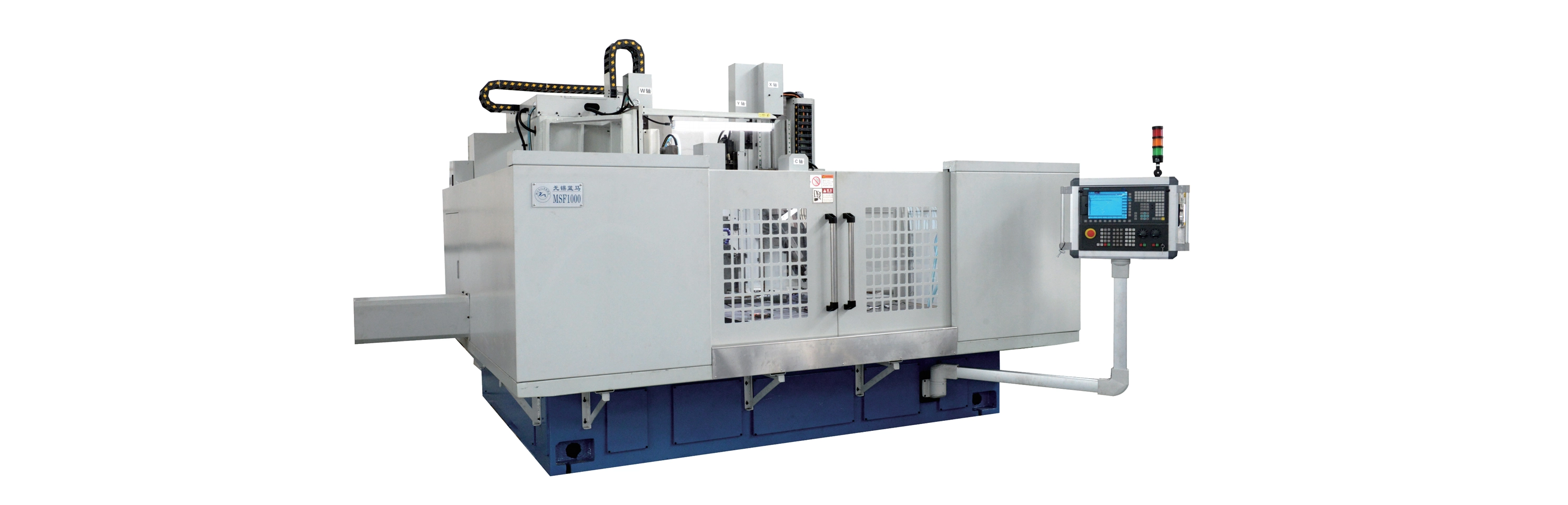

In modern manufacturing, a superfinish machine is used to achieve these results with controlled oscillation, pressure, and abrasive contact — ensuring consistency and repeatability across mass production lines.

Superfinishing is a low-pressure, high-precision abrasive process. The workpiece (such as a bearing ring, crankshaft, or gear) is rotated while fine-grain abrasive stones or tapes oscillate against its surface.

During this contact:

The abrasive removes only 1–2 µm of material.

The peaks of surface asperities are leveled, while the valleys remain — creating a plateau surface.

This plateaued texture improves lubrication retention and reduces friction during operation.

Modern superfinish machines feature servo-controlled oscillation and proportional-pressure systems that ensure uniform material removal and stable process temperature, preventing thermal distortion.

The primary purpose of superfinishing is not geometry correction — that's what grinding and honing do — but micro-geometry optimization. It refines the surface layer to improve:

Wear resistance by removing micro-cracks and heat-affected zones.

Friction behavior through improved oil film stability.

Fatigue strength by reducing surface stress concentrations.

Dimensional stability during high-speed or high-load operation.

This makes the process essential in industries where precision, longevity, and efficiency are non-negotiable.

| Parameter | Typical Range | Effect |

Pressure (contact force) | 0.2 – 0.6 MPa | Controls cutting depth and uniformity |

Oscillation frequency | 50 – 60 Hz | Affects surface texture pattern |

Abrasive grit size | 600# – 2000# | Determines final surface roughness |

Lubrication | Oil or emulsion | Reduces friction and flushes debris |

Material removal | 1–2 µm | Prevents geometry change |

Advanced CNC-controlled superfinish machines automatically adjust these parameters based on part type, ensuring stable performance and consistent Ra values across batches.

Superfinishing is indispensable in industries where surface performance defines product reliability.

Used for crankshafts, camshafts, gears, and transmission shafts, where reduced friction translates directly to higher fuel efficiency and lower noise.

Superfinishing improves the raceway surface of inner and outer rings, achieving the ultra-smooth, plateaued finish needed for long fatigue life and low vibration.

Critical parts such as turbine shafts, actuator rods, and spindles require micro-level smoothness to endure high-speed rotation and cyclic stress.

Valve spools, pistons, and sleeves are superfinished to ensure tight sealing, smooth sliding, and reduced leakage.

Used in implants and surgical instruments, where surface integrity affects biocompatibility and corrosion resistance.

The process eliminates the deformation and heat-affected zone left by grinding, restoring a stress-free, structurally sound surface.

By removing microscopic surface peaks, superfinishing reduces the coefficient of friction by up to 50%, significantly extending component life.

The plateaued texture holds lubricant more effectively, maintaining a stable oil film even under extreme load conditions.

Components superfinished with a superfinish machine can achieve 20–40% longer service life, thanks to minimized surface stress and improved lubrication behavior.

CNC-controlled machines provide uniform results, independent of operator skill — essential for mass production and global OEM standards.

The purpose is to improve surface integrity and tribological performance — reducing friction, enhancing lubrication, and extending the fatigue life of precision components.

Polishing improves visual appearance, while superfinishing enhances functional performance. It removes the damaged surface layer left by grinding and creates a plateaued texture ideal for moving, lubricated parts.

A superfinish machine uses oscillating abrasive tools under low pressure, combined with rotation and lubrication, to gently remove microscopic material and create a consistent, ultra-smooth surface finish.

Depending on the material and abrasive used, Ra ≤ 0.01–0.02 µm is achievable — significantly smoother than grinding or honing.

Primarily in automotive, aerospace, bearing, hydraulic, and precision manufacturing industries where component life, reliability, and noise reduction are key performance metrics.

The superfinishing process is a cornerstone of modern precision manufacturing.

By bridging the gap between geometry accuracy (from grinding) and surface perfection (from polishing), it ensures that components meet the strictest performance and durability standards.

For manufacturers seeking consistency, high productivity, and long-term reliability, investing in a high-quality superfinish machine is not just a technological upgrade — it's a competitive advantage that enhances both product quality and brand reputation.

What Industries Benefit Most from Super Finisher Machines?November 14, 2025Industries that require high precision, low friction, and long component life benefit most from super finisher machines — including automotive, aerospace, bearing manufacturing, hydraulic, medical, a...view

What Industries Benefit Most from Super Finisher Machines?November 14, 2025Industries that require high precision, low friction, and long component life benefit most from super finisher machines — including automotive, aerospace, bearing manufacturing, hydraulic, medical, a...view Achieving Mirror-Like Surface Finishes: Super Finishing vs. Traditional MethodsSeptember 3, 2025When it comes to mirror-like surface finishes, traditional processes such as grinding, lapping, or polishing can only go so far. They remove material effectively but often leave directional marks, hea...view

Achieving Mirror-Like Surface Finishes: Super Finishing vs. Traditional MethodsSeptember 3, 2025When it comes to mirror-like surface finishes, traditional processes such as grinding, lapping, or polishing can only go so far. They remove material effectively but often leave directional marks, hea...view Superfinishing Machine: How to Achieve Perfect Surface Finish?January 13, 2026Superfinishing Technology: A Flexible and Versatile Surface Treatment TechniqueSuperfinishing is a high-precision surface treatment technology designed to remove debris and metal particles left from p...view

Superfinishing Machine: How to Achieve Perfect Surface Finish?January 13, 2026Superfinishing Technology: A Flexible and Versatile Surface Treatment TechniqueSuperfinishing is a high-precision surface treatment technology designed to remove debris and metal particles left from p...view Call us on:

Call us on:  Email Us:

Email Us:  No. 52-1 Zhang Road, Meicun Industrial Park, New District, Wuxi City, Jiangsu, China.

No. 52-1 Zhang Road, Meicun Industrial Park, New District, Wuxi City, Jiangsu, China.