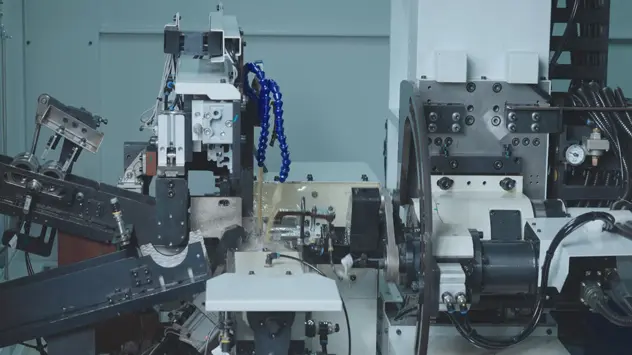

The automatic bearing inner and outer ring groove superfinishing machine for Deep Groove Ball Bearings is a precision-engineered device designed to enhance the surface finish and roundness of ball bearings. Utilizing advanced abrasive techniques, it ensures minimal surface roughness and optimal geometric accuracy, thereby extending the bearing’s lifespan and performance. Ideal for high-precision applications, this machine offers automated operation, consistent results, and reduced processing time. Its robust construction and user-friendly interface make it a reliable choice for manufacturers aiming for superior quality and efficiency in bearing production.

A superfinishing machine significantly enhances the performance of deep groove ball bearings by refining the surface finish of the bearing components. This process reduces surface roughness, leading to lower friction and wear during operation. The improved surface quality ensures better lubrication retention, which minimizes heat generation and extends the bearing’s lifespan. Additionally, superfinishing helps in achieving tighter dimensional tolerances, resulting in more precise and consistent bearing performance. Overall, the enhanced surface integrity and reduced imperfections contribute to smoother operation, increased efficiency, and greater reliability of deep groove ball bearings in various applications.

The typical cycle time for superfinishing a deep groove ball bearing can vary depending on several factors, including the size of the bearing, the specific superfinishing process used, and the desired surface quality. Generally, the cycle time ranges from a few minutes to around 20 minutes per bearing. Superfinishing aims to achieve a high-quality surface finish, reduce friction, and extend the bearing’s operational life. Advanced superfinishing techniques and equipment can optimize the process, potentially reducing cycle times while maintaining or improving surface quality. For precise cycle times, consulting with equipment manufacturers or process engineers is recommended.

Call us on:

Call us on:  Email Us:

Email Us:  No. 52-1 Zhang Road, Meicun Industrial Park, New District, Wuxi City, Jiangsu, China.

No. 52-1 Zhang Road, Meicun Industrial Park, New District, Wuxi City, Jiangsu, China.