Full-automatic wheel hub inner (outer) ring dual station groove bearing superfinishing machine for upper/lower grooves, 25-35s/piece. Features touch-screen control, servo precision, oil mist lubrication, and space-saving design.

Innovative Dual-Station Design

Simultaneous Upper/Lower Groove Processing – Maximize throughput by machining both surfaces in a single operation

Space-Optimized Footprint – Compact layout saves valuable floor space without compromising functionality

Premium Performance Features

Intuitive Touch-Screen Control – User-friendly interface for seamless operation and quick changeovers

Servo-Driven Precision – Ensures micron-level accuracy for perfect bearing seat every time

Advanced Oil Mist Lubrication – Extends tool life and maintains consistent machining quality

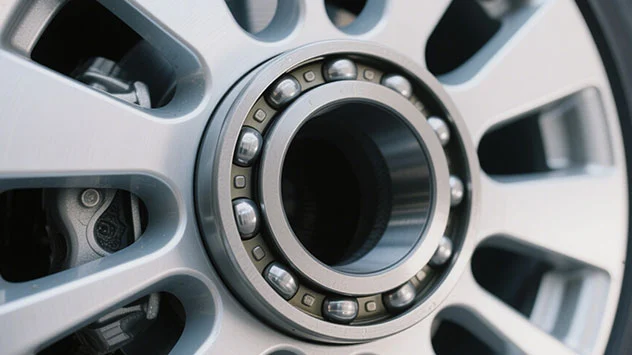

Automotive wheel hub bearings require materials that can withstand high loads, speeds, and environmental conditions. The most suitable materials for superfinishing in these bearings include high-carbon chrome steel (e.g., AISI 52100), bearing steel (e.g., 100Cr6), and stainless steel. These materials offer excellent wear resistance, fatigue strength, and corrosion resistance. Ceramic materials may also be used for high-performance applications, providing superior hardness and reducing friction. The superfinishing process improves surface smoothness, reducing friction and wear, which is crucial for enhancing the bearing's longevity, reducing noise, and improving the overall performance of the wheel hub assembly.

Using a superfinishing machine for automotive wheel hub bearings offers several key benefits. It significantly improves surface quality by reducing roughness and eliminating imperfections, which lowers friction and wear. This enhances the bearing's overall performance, increasing its efficiency and load capacity. A smoother surface also extends the bearing’s lifespan, reducing the risk of premature failure. Additionally, superfinishing helps in minimizing noise and vibration during operation, contributing to a smoother ride. In high-speed and heavy-load automotive applications, superfinishing ensures that wheel hub bearings perform reliably and efficiently, improving both vehicle safety and durability.

Call us on:

Call us on:  Email Us:

Email Us:  No. 52-1 Zhang Road, Meicun Industrial Park, New District, Wuxi City, Jiangsu, China.

No. 52-1 Zhang Road, Meicun Industrial Park, New District, Wuxi City, Jiangsu, China.