Standard: ≤0.5µm (ask for test reports).

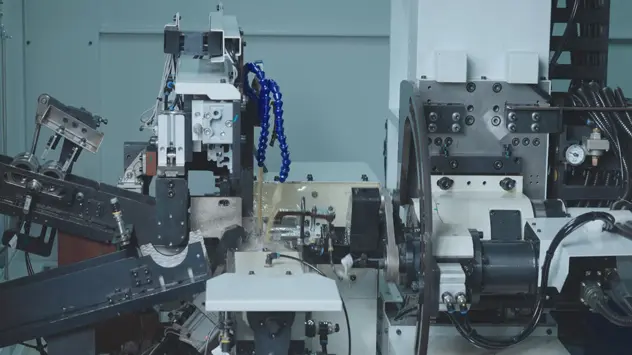

We specialize in delivering top-tier superfinishing machines designed to meet the highest industry standards. Our cutting-edge technology ensures unparalleled precision, enhancing the performance and longevity of your components. With a dedicated team of experts, we offer personalized solutions tailored to your specific needs. Our commitment to quality, reliability, and customer satisfaction sets us apart. Choose us for innovative designs, robust construction, and exceptional after-sales support. Elevate your manufacturing process with our state-of-the-art superfinishing machines and experience the difference in efficiency and excellence.

Automotive Manufacturing – Delivers precision finishing for wheel bearings, transmission components, and EV drivetrain systems. Achieves surface finishes below Ra 0.1µm, reducing friction by 30-40% while extending service life by 2-3x. Critical for meeting stringent OEM noise/vibration standards.

Aerospace & Defense – Processes turbine shaft bearings, landing gear assemblies, and flight control actuators to withstand extreme operational conditions (-60°C to 300°C). Complies with AS9100/NADCAP requirements while maintaining micron-level tolerances for mission-critical reliability.

Industrial Machinery – Enhances bearing performance in wind turbine generators (3MW+), industrial robots, and high-speed spindles. The superfinishing process increases load capacity 20-25% and reduces energy consumption by 15% in continuous duty applications.

Standard: ≤0.5µm (ask for test reports).

Superfinishing machines can process a variety of materials including metals, ceramics, and composites.

25–35 seconds for small bearings (varies with complexity).

The process is controlled by adjusting parameters such as pressure, speed, and abrasive type.

Regular maintenance includes checking and replacing abrasives, lubricating moving parts, and ensuring proper alignment and calibration.

Call us on:

Call us on:  Email Us:

Email Us:  No. 52-1 Zhang Road, Meicun Industrial Park, New District, Wuxi City, Jiangsu, China.

No. 52-1 Zhang Road, Meicun Industrial Park, New District, Wuxi City, Jiangsu, China.